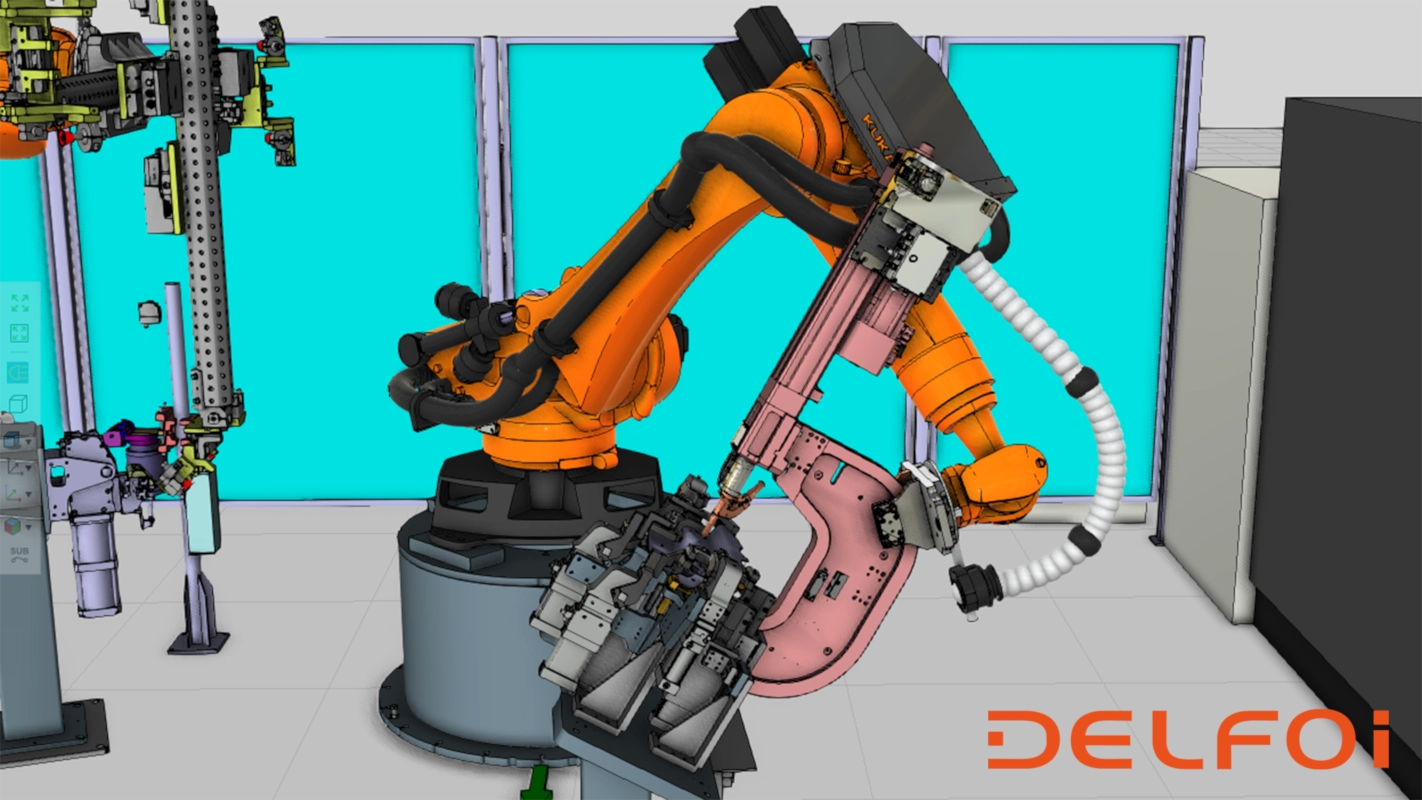

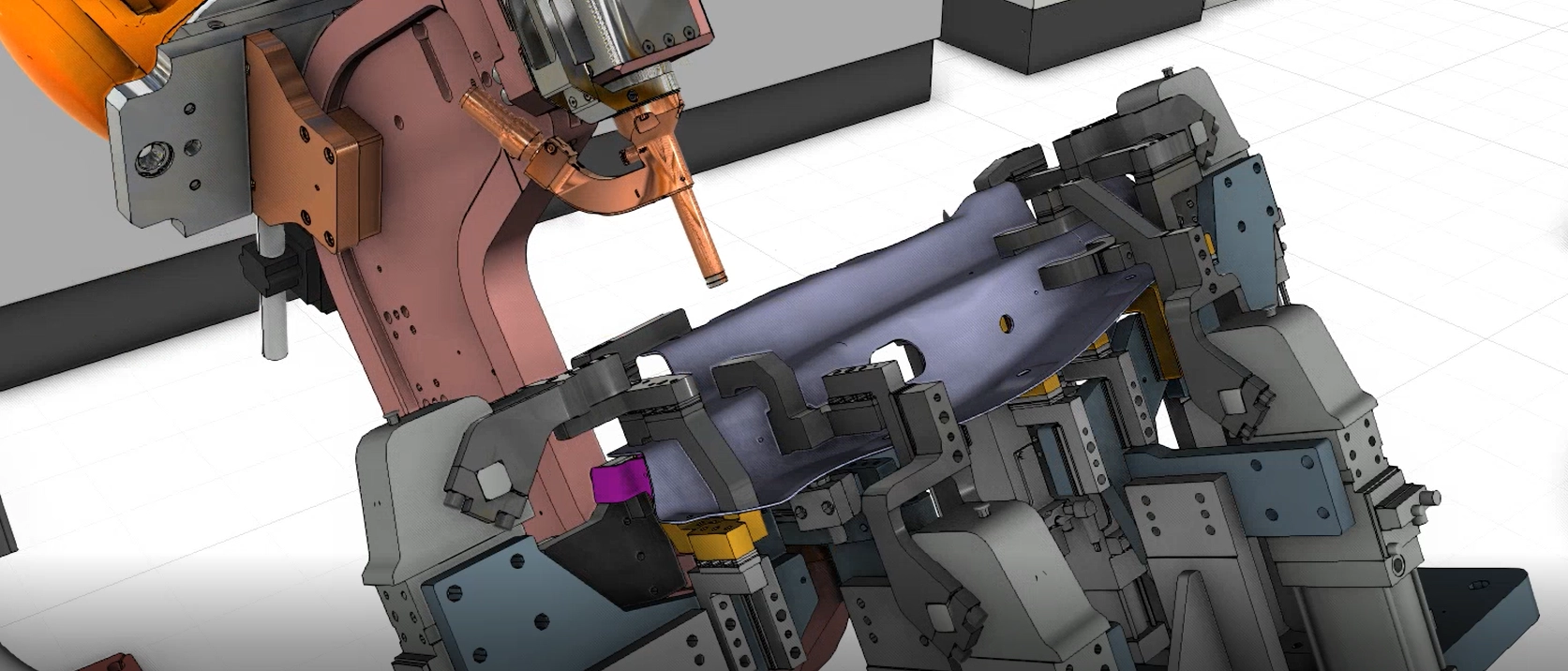

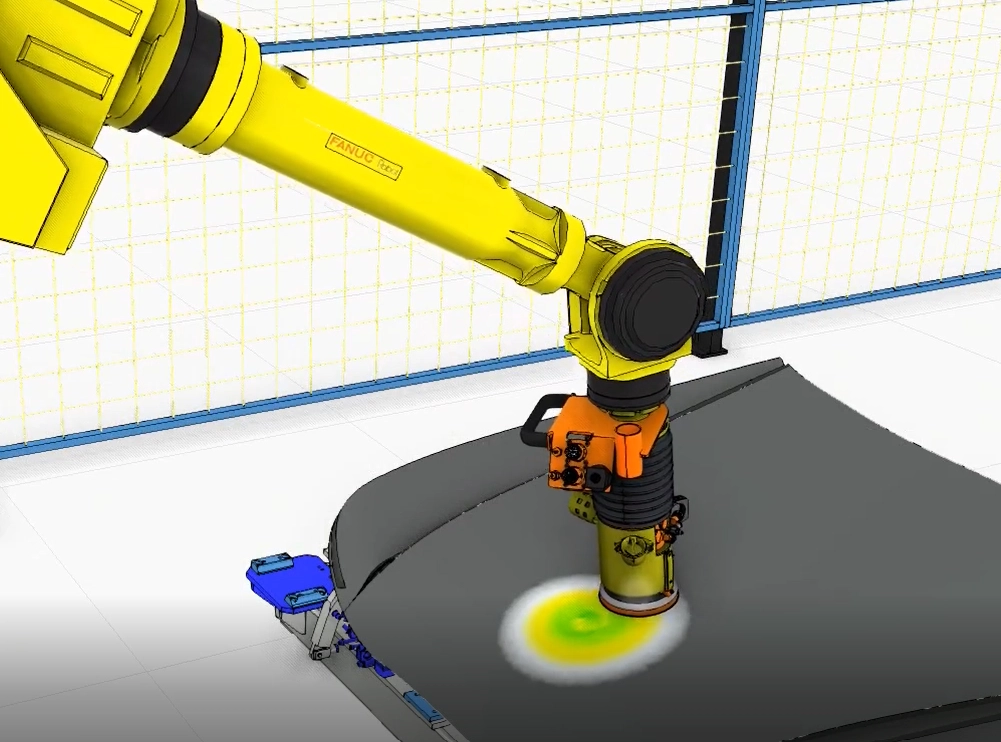

Visualcomponents OLP is a fast and intuitive solution for arc welding. It uses the 3D CAD model topology and with its own WPS (Welding Procedure Specification) database, creates accurate, error-free, homogeneous and high-quality welding.

Visual Components OLP

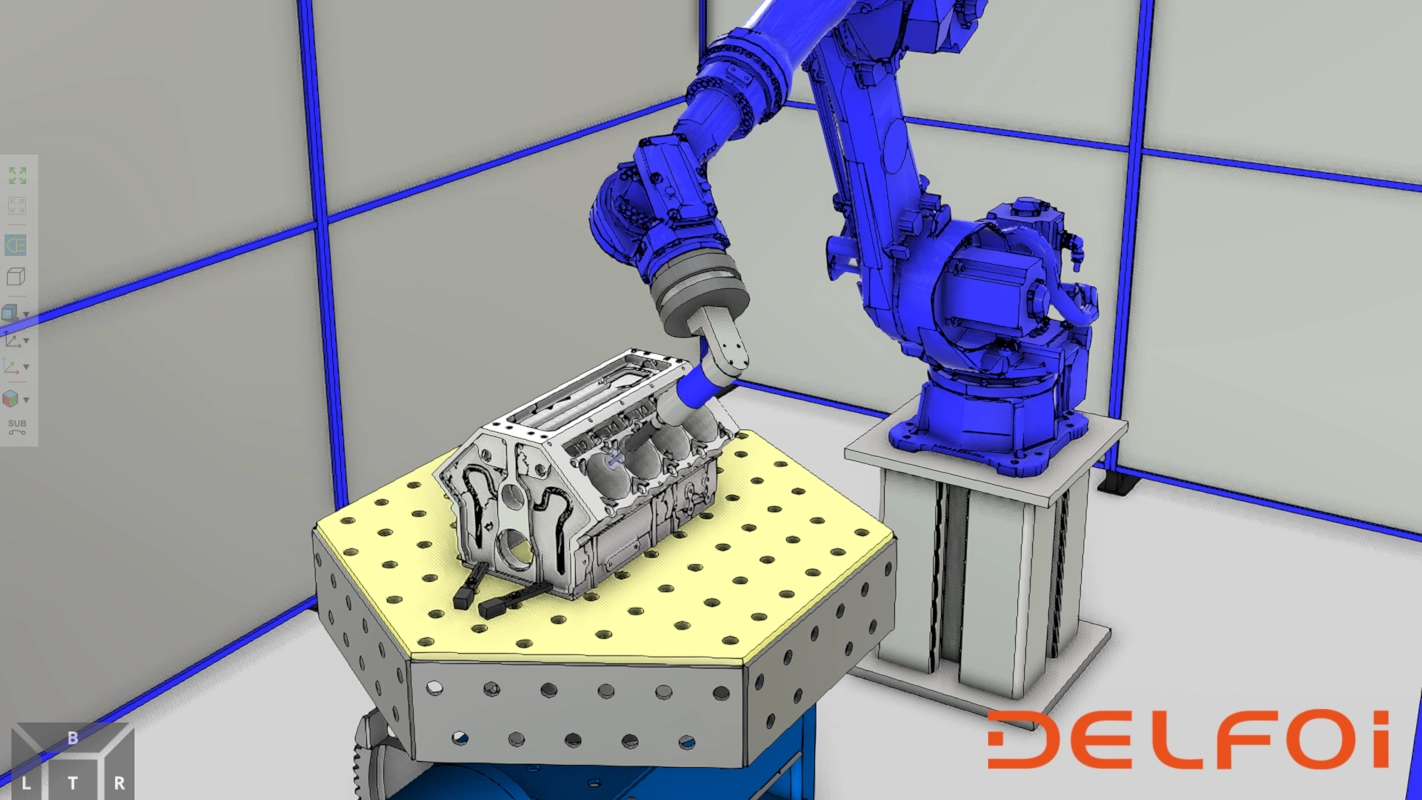

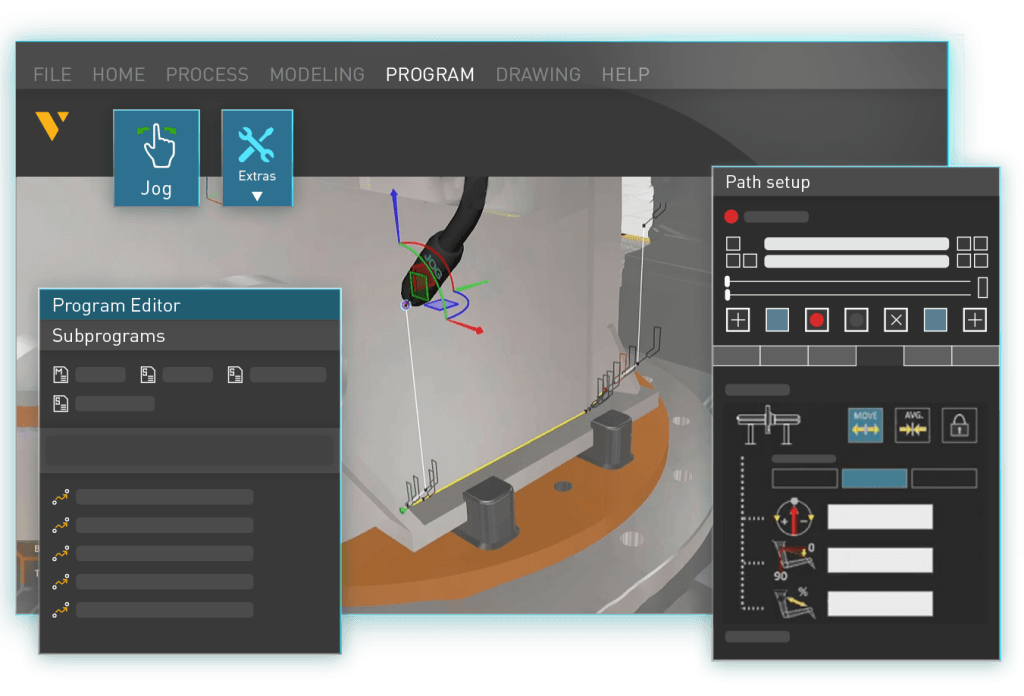

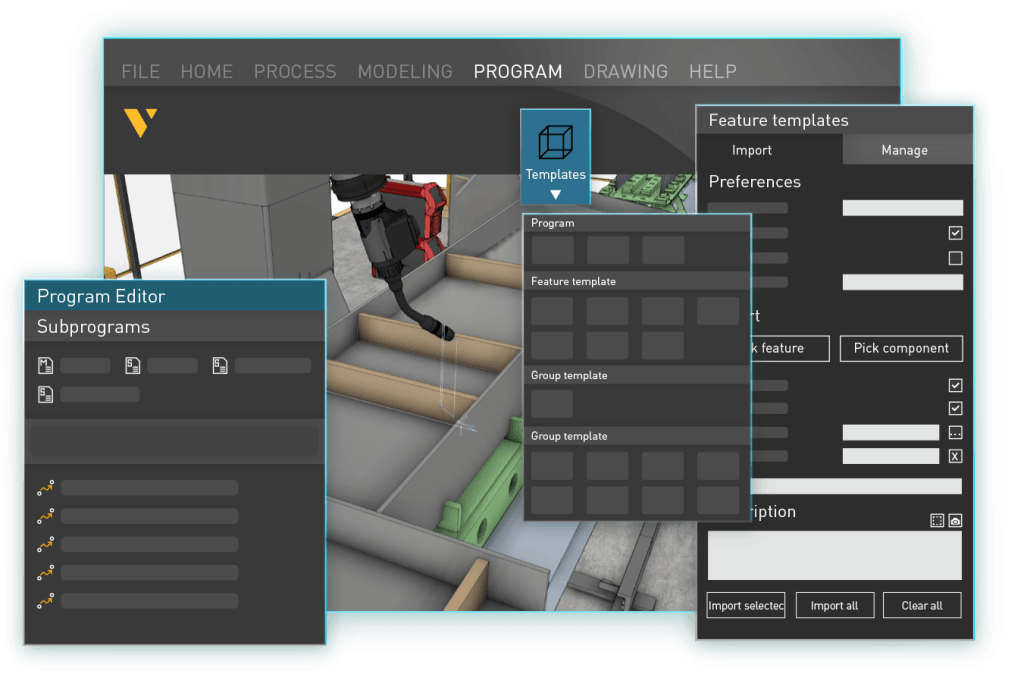

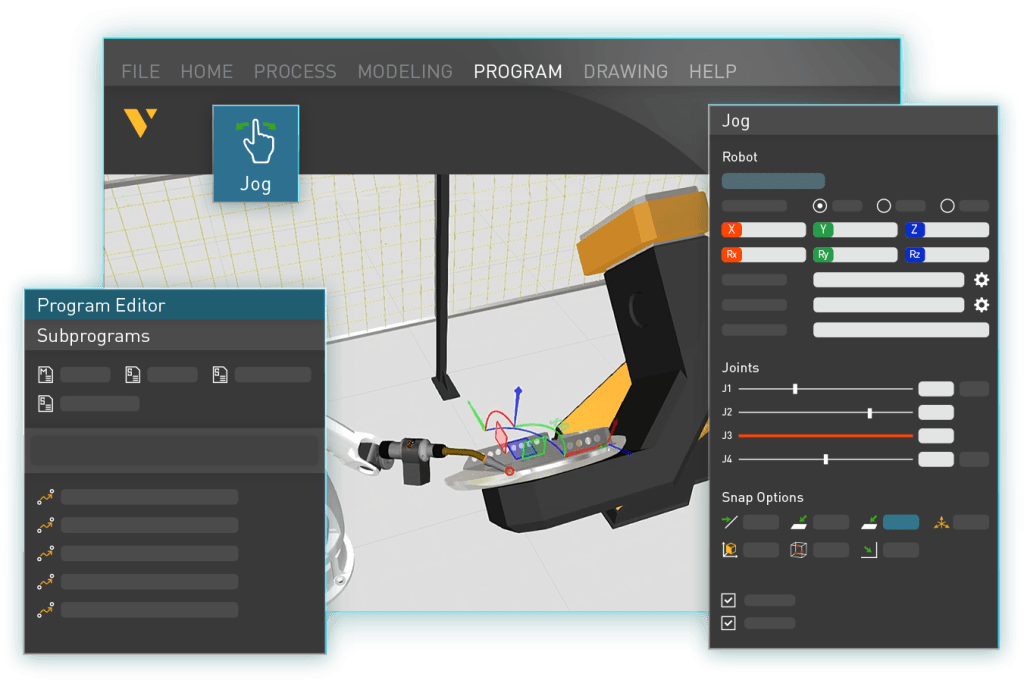

The next generation offline robot programming software, Visual Components OLP, is based on the powerful technology of Delfoi Robotics. It maximizes the potential of robots with fast, accurate and error-free programming solution.

This offline programming (OLP) software represent the most advanced offline programming technology available today. The software is unique where time, money and quality counts:

- Fast and easy: programming and trajectory/program editing

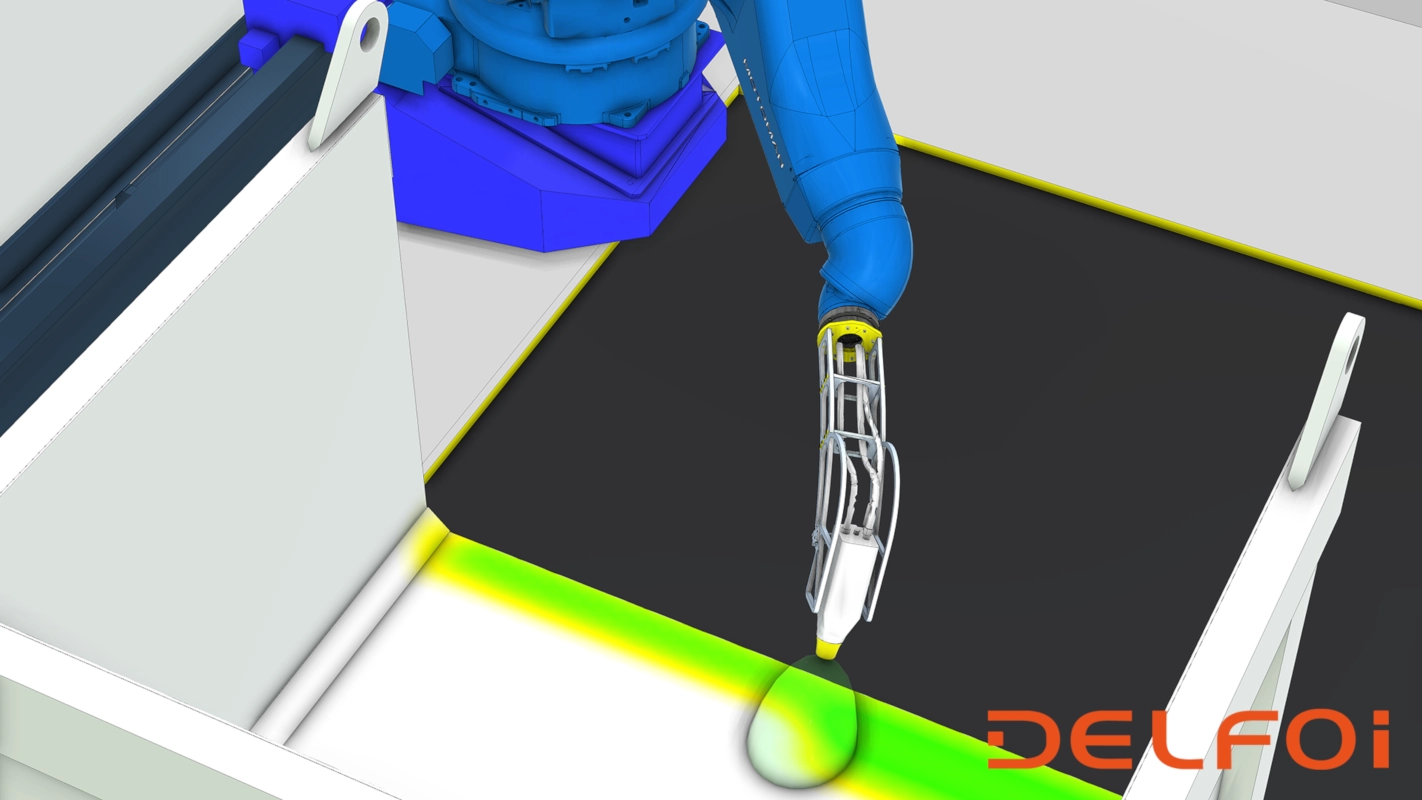

- Quality control: accurate and smooth trajectories

- Accurate tool paths: advanced calibration tools and trajectory management

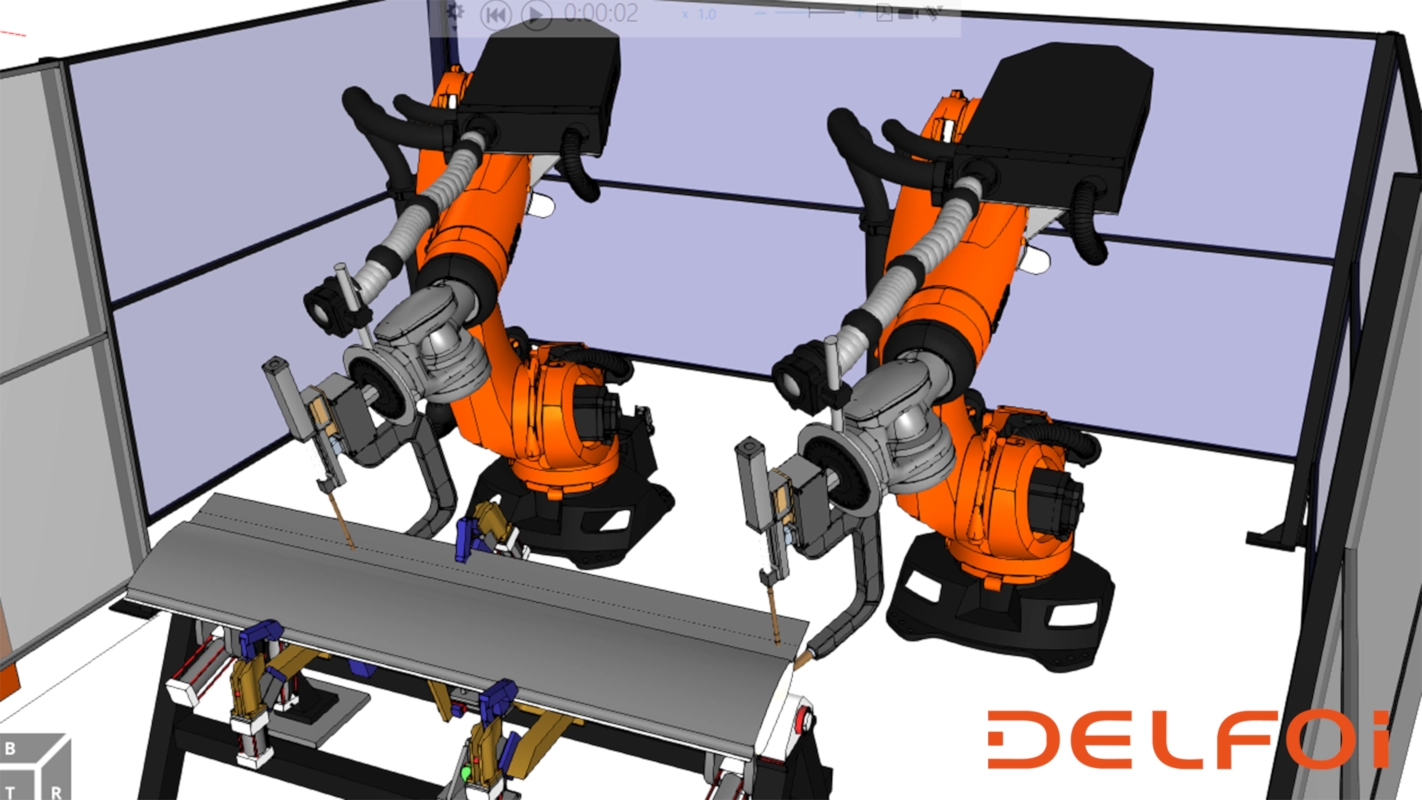

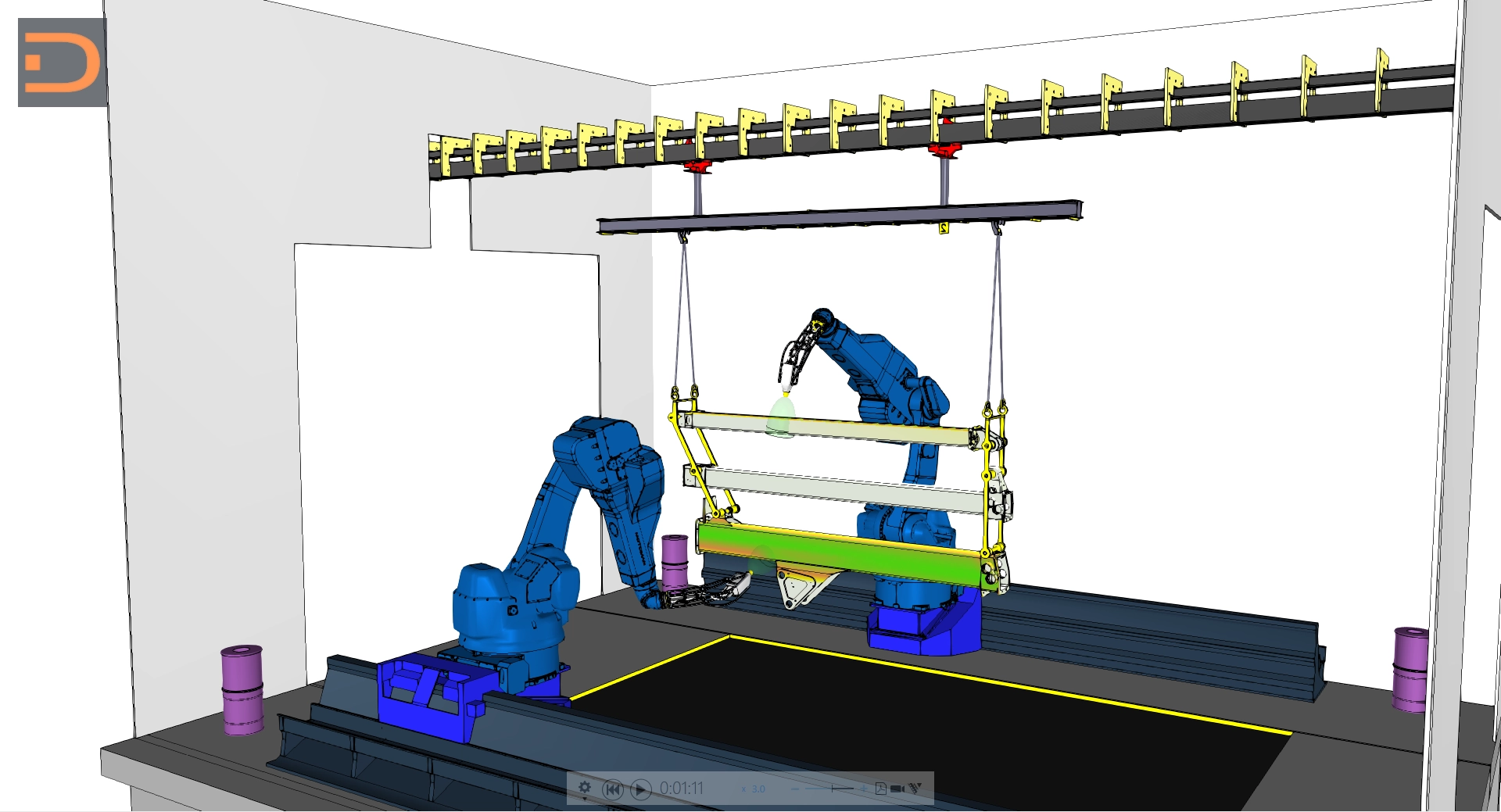

- One for all: support for all major robot brands; ABB, Fanuc, KUKA, Motoman, Panasonic,…

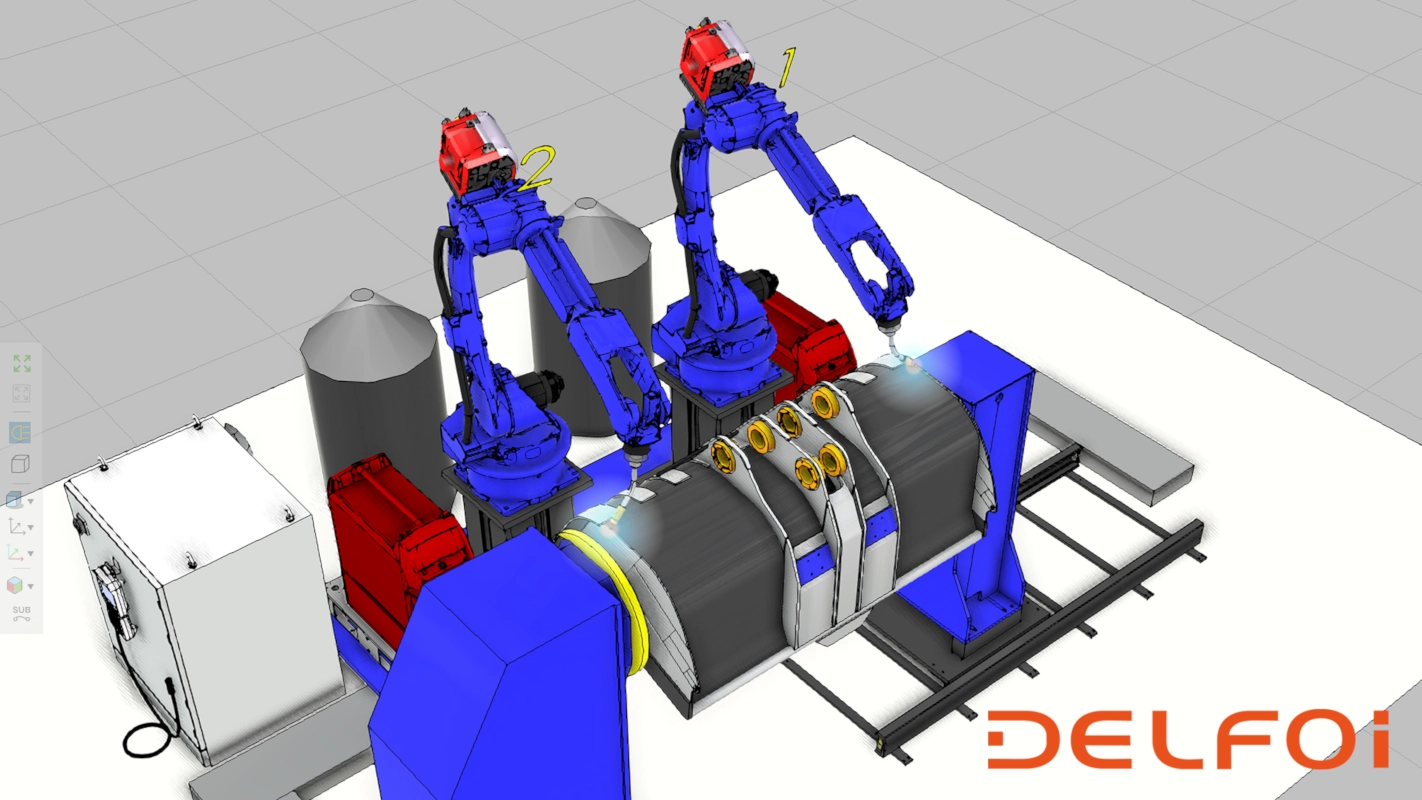

Visual Components OLP supports all major robot brands. The benchmark winning software is used for various industries including automotive, heavy machinery, aerospace, construction steel, and ship building all over the world.

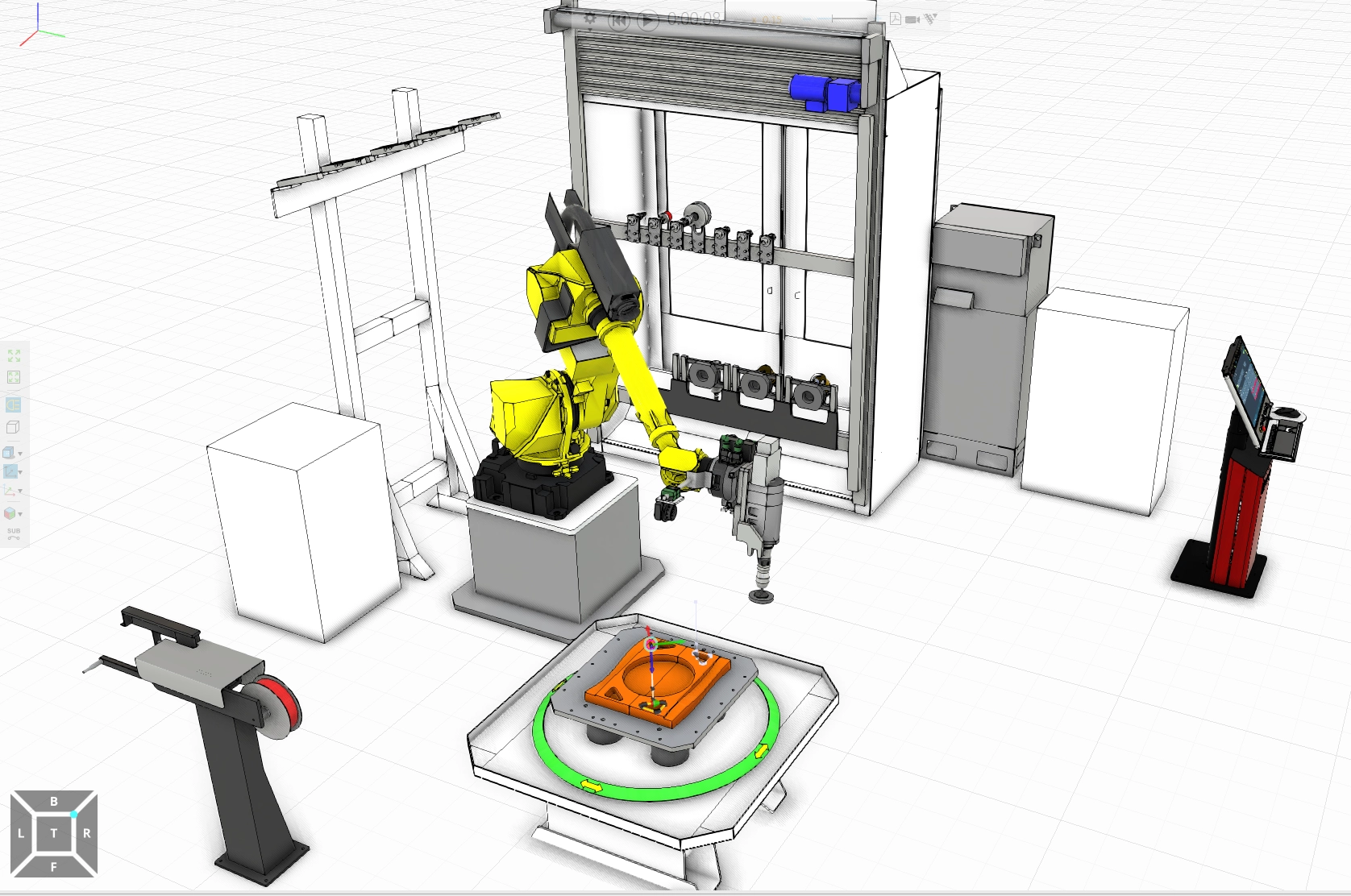

OLP is built using Visual Components proven simulation technology platform.

Consistent quality with excellent accuracy

Inconsistencies and errors compromise the repeatability of quality. Robot programming software should enable repeatable quality with accuracy and minimal waste from manufacturing design to production.

Accurate and error-free programs

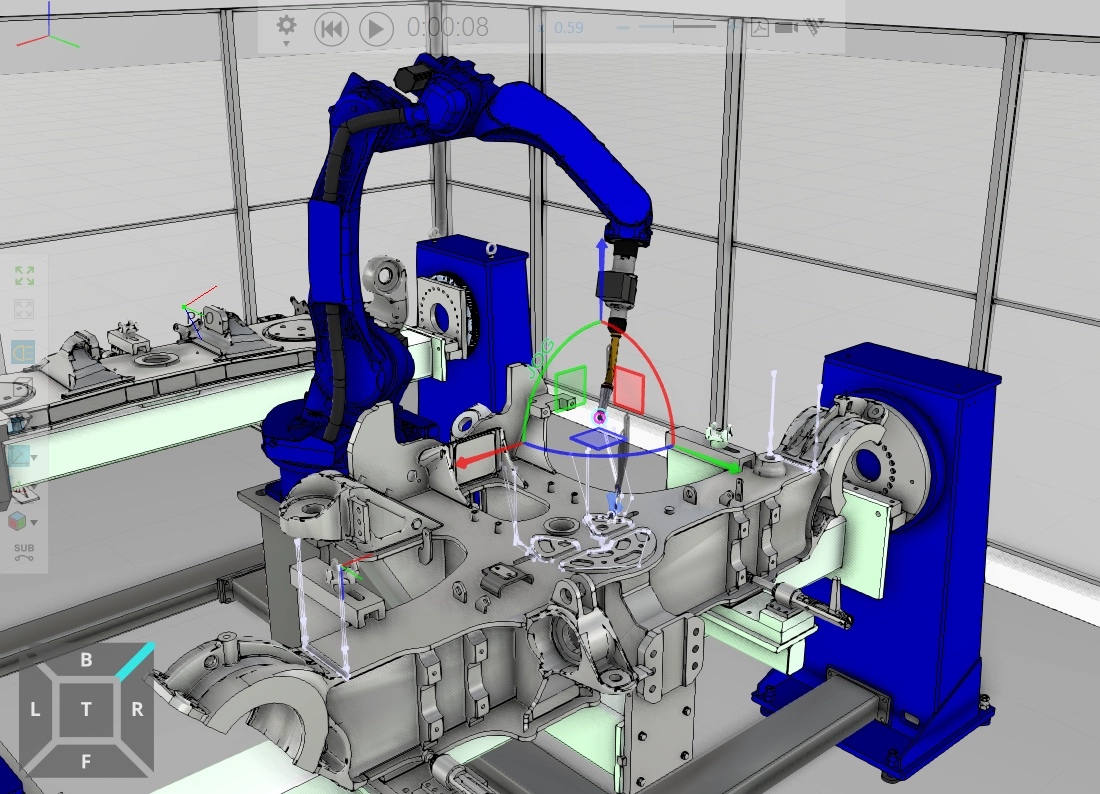

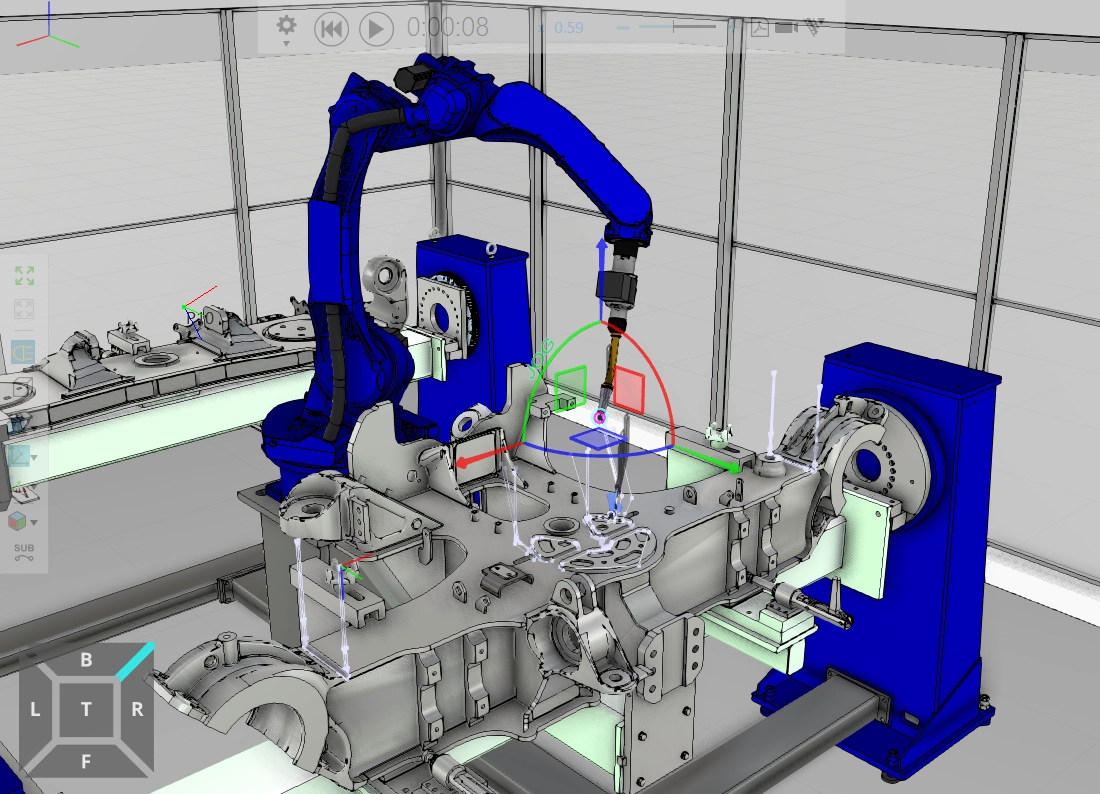

Easily calibrate robot layouts for accurate virtual-physical alignment. Let the software validate and optimize programs, eliminating costly production errors, part loss and risk.

Process knowledge database

Save your programs and re-use them anytime in the future for other projects and knowledge sharing.

Manufacturing feasibility

Eliminate last-minute modifications to fixtures and tooling, ensuring a smooth production process without unexpected delays and risks. Thoroughly test and adjust virtual models of the production setup well in advance of actual production.