Unlocking efficiency: the transformative benefits of offline programming (OLP)

Offline programming (OLP) offers numerous advantages for manufacturing companies. Firstly, it significantly reduces downtime by allowing robots to continue working while new programs are developed and tested in a virtual environment. This not only increases efficiency but also improves production quality by enabling the refinement of programs before real-world implementation. Additionally, OLP makes programming accessible even to non-experts by capturing and standardizing the expertise of seasoned programmers.

Benefits of OLP

- Reduced Downtime: Robots can continue working while being programmed offline.

- Lower Programming Costs: Reduces costs associated with programming without costly interruptions.

- Improved Quality: More precise and optimized programs improve the quality of finished products.

- Accessibility of Expertise: Standardizes the knowledge of expert programmers, making skills accessible to less experienced users.

Companies of all sizes can benefit from OLP, but it is particularly advantageous for small and medium-sized enterprises that cannot afford long downtimes for robot programming. Sectors handling small production batches or requiring frequent process changes also find OLP indispensable.

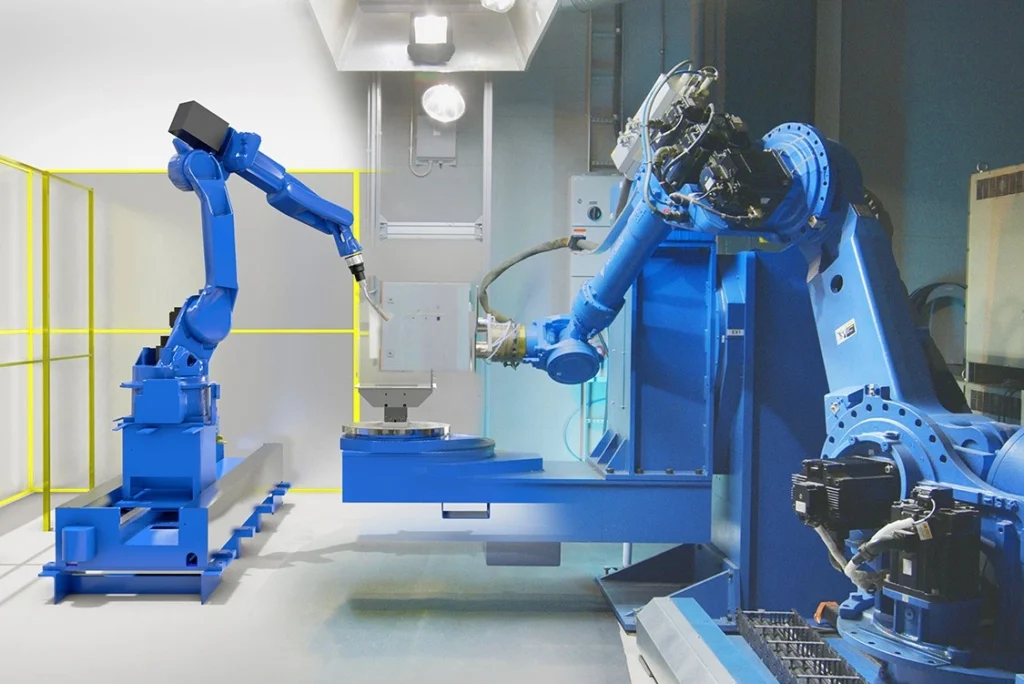

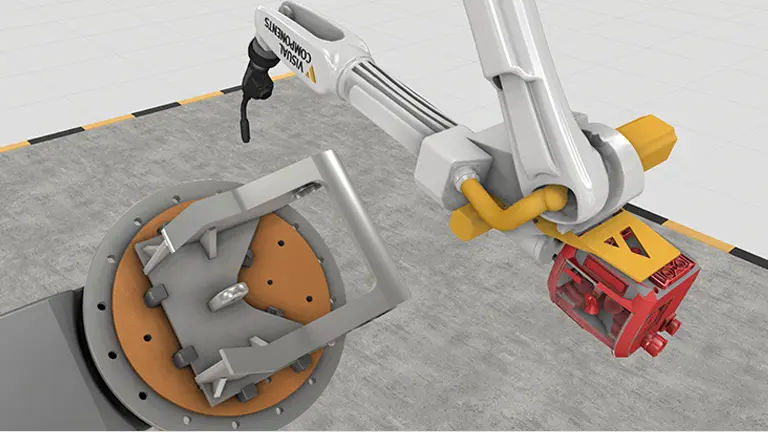

OLP is applicable in many industrial processes. For example, in welding, it improves precision and consistency, reducing defects and repair costs. In plasma cutting, it optimizes cutting paths, ensuring greater precision. For grinding and surface finishing, OLP automates and optimizes these processes, improving the quality of treated surfaces and reducing processing times. In assembly, it allows the programming and testing of complex components in a virtual environment, increasing efficiency and reducing errors.

Efficiency and KPIs achieved with OLP

- Reduced Setup Time: Decrease of 50-70% in setup times.

- Increased Productivity: Productivity increases of 30-50% in various industrial sectors.

- Improved Quality: Significant reduction in production defects.

- Rapid ROI: Return on investment within a few months.

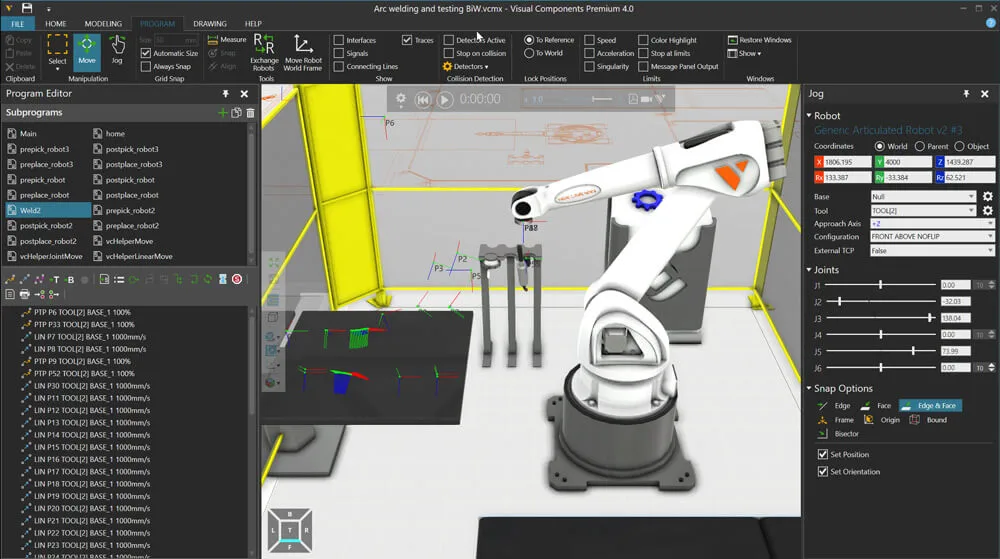

Visual Components OLP stands out for its intuitive interface, multi-brand support, advanced simulation capabilities, and CAD data integration. This mature software, backed by decades of experience, offers comprehensive solutions for offline programming, significantly enhancing productivity and production quality.

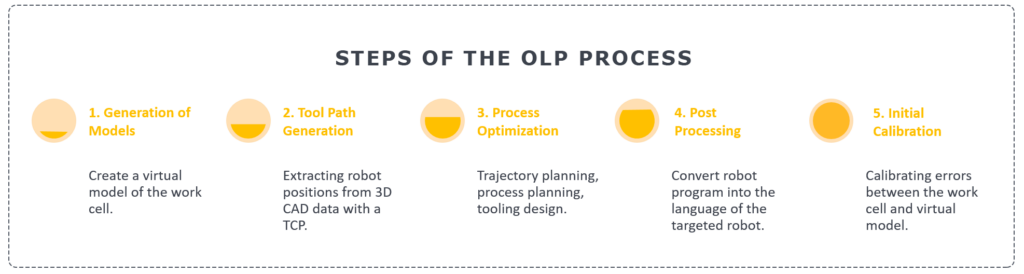

Streamlining production: the essential steps for effective OLP setup

Creating an offline programming (OLP) setup involves five key steps. First, generate a virtual model of the work cell to simulate the environment. Next, generate the tool path by extracting robot positions from 3D CAD data, often automated by OLP software to recognize features like corners and edges. The third step is process optimization, which includes trajectory planning and tooling design, using simulation to refine the process iteratively. After optimization, post-processing converts the verified program into the specific language of the target robot, with customized post processors for each application. Finally, initial calibration aligns the virtual model with the physical work cell, ensuring accurate execution without unplanned operator intervention. Calibration can be done either offline or directly in the production environment, depending on the application requirements.

Offline programming (OLP) offers numerous advantages for manufacturing companies. Firstly, it significantly reduces downtime by allowing robots to continue working while new programs are developed and tested in a virtual environment. This not only increases efficiency but also improves production quality by enabling the refinement of programs before real-world implementation. Additionally, OLP makes programming accessible even to non-experts by capturing and standardizing the expertise of seasoned programmers.

If you want to learn more about how Visual Components OLP can revolutionize your production, contact Flexcon for a DEMO. Maximize the potential of offline programming and take your company to the next level.

Contact Flexcon: master OLP for optimal production with Visual Components OLP.