Simulation software included in Transizione 5.0 Measure for operational efficiency

Italian Companies looking to invest in innovation and process optimization have a unique opportunity: software can be included in the Transizione 5.0 measure, provided it is part of projects aimed at improving operational efficiency.

With the window for completing investments closing by 2025, Italian industry faces a crucial challenge in adapting to the Transizione 5.0 measure. During the Ambrosetti Forum, Italian Prime Minister Giorgia Meloni hinted at a possible extension, but the minister of enterprises and made in Italy, Adolfo Urso, clarified that without approval from the European Commission, deadlines will not be altered.

Key to digital transformation

The recent operational circular of August 16, 2024, clarified that software falls under intangible assets defined by law no. 232 of December 11, 2016, in annexes A and B. Specifically, the “allegato B typology table” lists 3D design software and software for robotic applications as tools eligible for the incentive. This includes software for modeling, simulating, and optimizing production processes, now part of the innovation framework.

Simulation and energy savings

Simulation software like FlexSim and Visual Components can play a critical role in optimizing production systems. These tools don’t directly monitor energy use but improve plant performance by identifying bottlenecks early in design. By boosting efficiency, they help reduce energy use, aligning with Transizione 5.0 goals.

These types of software fall under categories such as:

- 3D design software: tools for the 3D design, simulation, and verification of production processes, as defined in section 1.1 of the circular, which includes software for performance analysis and digital archiving of the product life cycle.

- Robotics software: systems that optimize the use of robots and intelligent machines in production lines, enhancing product quality and safety, and supporting predictive maintenance, as indicated in section 1.15 of the circular.

Simulation for a more efficient future

Even with only 15 months remaining, companies can still fully capitalize on this opportunity by using advanced simulation tools like FlexSim and Visual Components to optimize production processes. This not only helps in reducing energy consumption but also ensures a smoother transition towards more efficient and sustainable production systems.

For more information on how these tools can support your innovation projects, contact Flexcon today.

A closer look at Flexcon‘s solutions

Within this framework, Flexcon offers two powerful solutions that fit perfectly within the guidelines of Transizione 5.0:

- FlexSim: a state-of-the-art 3D simulation software designed to model, visualize, and optimize production systems. FlexSim enables companies to simulate workflows, identify bottlenecks, and test various production scenarios before making real-world changes. By improving overall efficiency, FlexSim contributes indirectly to energy savings, helping companies align with the goals of the Transizione 5.0 incentive.

- Visual Components: ideal for robotics applications, Visual Components is a 3D simulation and offline programming tool specifically designed for manufacturing robotics. It facilitates the design and optimization of robotic work cells and production lines. Thanks to advanced features for ergonomics and collision detection, it improves human-robot collaboration, reduces operational risks, and optimizes system integration. Visual Components boosts productivity and energy efficiency through better robotic system use, as noted in the circular’s robotics software section.

For more information on how FlexSim and Visual Components can support your innovation projects, contact us today.

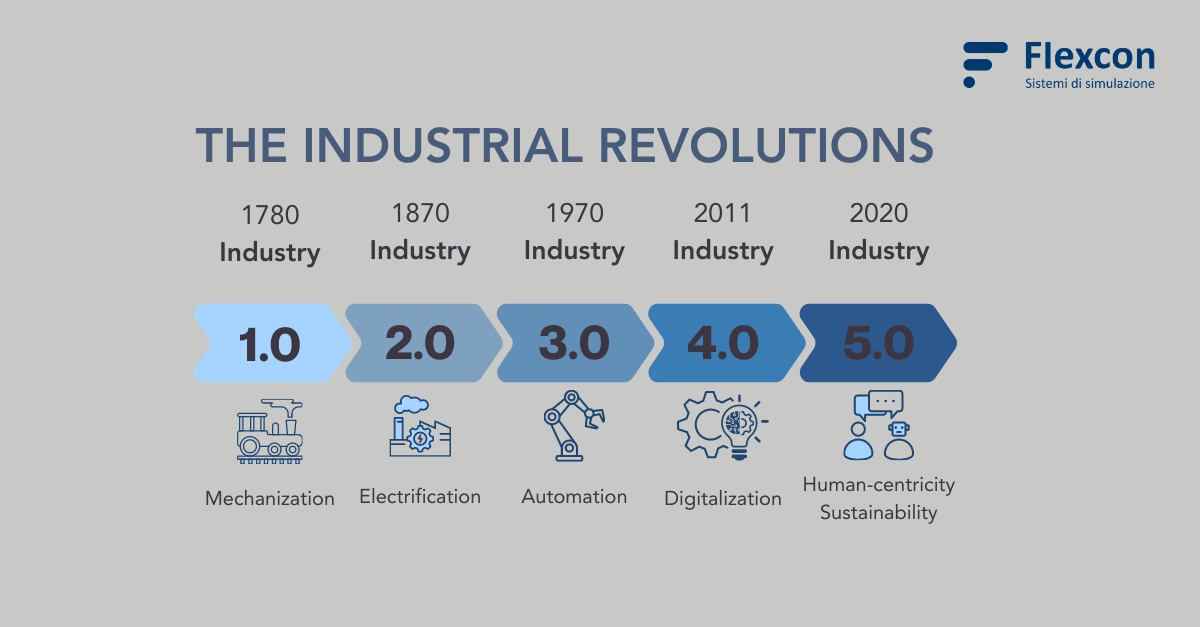

Contact Flexcon: learn more about Simulation Solutions for Industry 5.0.