Integrating process simulation with design tools: the rationale behind Autodesk’s acquisition of FlexSim

FlexSim acquisition by Autodesk was completed in November 2023, shortly after the announcement of plans to integrate process simulation with native design tools already available on its platforms. This swift completion underscores Autodesk’s commitment to rapidly integrating FlexSim’s advanced simulation technology into its suite of tools. This acquisition allows Autodesk to enhance its digital factory design and operational efficiency capabilities. It positions Autodesk as a leader in providing comprehensive, cloud-connected solutions for the entire lifecycle of manufacturing and logistics operations. This strategic move not only fortifies Autodesk’s offerings but also delivers immediate value to its customers, enabling them to tackle contemporary industry challenges with innovative, integrated solutions.

Autodesk’s strategic acquisition of FlexSim and its industry-leading features

If a top multinational corporation makes the move to acquire a platform like Flexsim, it cannot be accidental. It must be part of a strategic plan reflecting the ambitions of this prestigious brand. The goal is to enhance factory design solutions and make a significant impact on its customers. This strategy is to facilitate digital transformation in manufacturing and logistics, addressing critical industry needs for efficiency and sustainability.

Integration of simulation with design tools

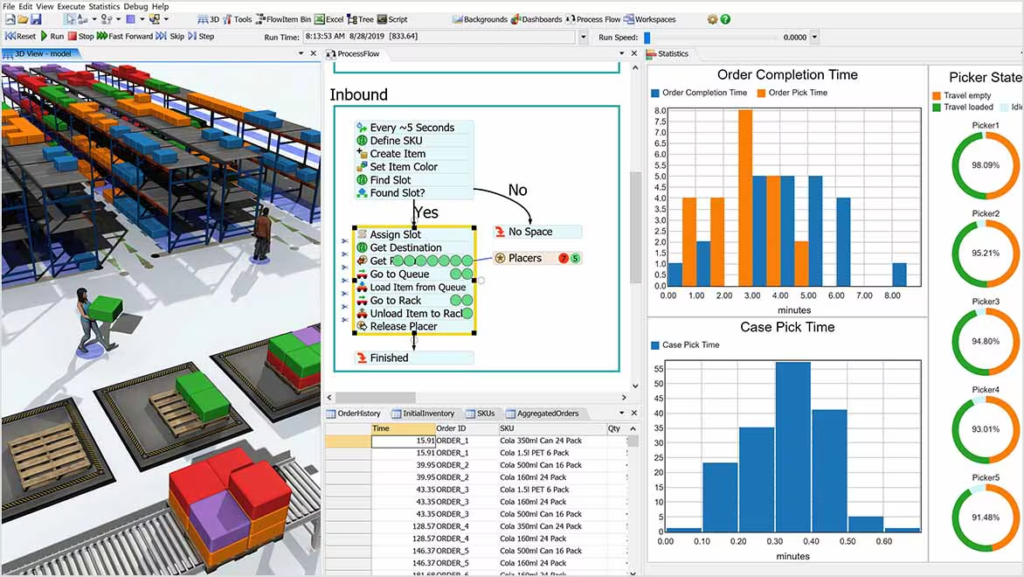

FlexSim’s simulation technology lets manufacturers create detailed models of factory floors and logistics centers. This provides valuable insights into production flow and performance metrics. Integrating FlexSim with Autodesk’s design tools, such as Inventor, Revit, AutoCAD, and Autodesk Construction Cloud, allows users to transition seamlessly from design to operational analysis within a unified platform.

Addressing industry challenges

Manufacturers are under pressure to optimize operations due to rising energy and material costs, stringent environmental regulations and the need to relocate and relocate production. FlexSim’s simulation technology provides a powerful solution, enabling comprehensive analysis and optimization of factory and logistics center operations. The task of Industry 4.0 and 5.0 is to provide manufacturers with tools to achieve greater efficiency, reduce costs and improve sustainability by putting it at the center of the enterprise.

Enhancing digital twins

One of the standout benefits of FlexSim’s technology is its ability to create digital twins—high-resolution virtual replicas of physical factories. These digital twins allow for detailed simulation and control of operations. They enable accurate performance prediction, energy consumption forecasting, safety analysis, and equipment utilization measurement. Integrating FlexSim with one of the largest modeling platforms worldwide strengthens the digital twin concept, making it more accessible and actionable for manufacturers.

FlexSim’s best features in today’s industry

Discrete event simulation (DES)

FlexSim excels in discrete event simulation, modeling systems as a sequence of discrete events over time. This method is effective for analyzing complex manufacturing processes and logistics operations. It helps identify bottlenecks, optimize workflows, and predict system behavior in various scenarios.

Advanced modeling and analysis

FlexSim provides robust tools for in-depth model analysis and layout scenarios. Users can simulate different factory layouts and processes, enabling them to test and refine their designs before implementation. This capability significantly reduces the risk of costly mistakes and inefficiencies that can arise from poor planning and design.

Real-time data integration

A key feature of FlexSim is its ability to integrate real-time operational data with factory design data. This integration ensures that simulations are based on current and accurate information, enhancing the reliability of the insights generated. This capability is crucial for maintaining a responsive and adaptive manufacturing environment, where changes can be quickly evaluated and implemented.

Cloud connectivity

FlexSim’s technology supports cloud-based data management, aligning perfectly with Autodesk’s cloud-first strategy. Centralized and connected data ensures that all stakeholders have access to up-to-date information, breaking down silos and improving communication and collaboration. This connectivity facilitates a continuous improvement loop. Lessons learned from each simulation can be applied to subsequent iterations, driving ongoing operational enhancements.

Predictive analytics and optimization

FlexSim’s simulation capabilities extend beyond mere modeling to include predictive analytics and optimization. Users can forecast the impact of changes in their production processes, evaluate different scenarios, and identify the optimal solutions. This proactive approach to management enables manufacturers to stay ahead of potential issues, streamline their operations, and make data-driven decisions that enhance productivity and reduce costs.

To learn more about the strategic steps that Autodesk is taking to expand its capabilities and leveraging artificial intelligence to improve automation and creativity in design and manufacturing, check out this interesting article.

The acquisition of FlexSim by Autodesk represents a strategic enhancement of Autodesk’s manufacturing and logistics solutions. By integrating advanced simulation capabilities with existing design tools, Autodesk is well-positioned to help manufacturers navigate the complexities of modern production environments. FlexSim’s robust features, including discrete event simulation, advanced modeling, real-time data integration, cloud connectivity, and predictive analytics, provide powerful tools for optimizing factory and logistics operations. This acquisition underscores a big corporate’s commitment to driving digital transformation in manufacturing, enabling businesses to achieve greater efficiency, sustainability, and competitiveness in a rapidly evolving industry.

Contact Flexcon: discover how to get a free trial version of FlexSim and transform your factory operations with cutting-edge simulation technology.